What Is Just-In-Time? The Role Of JIT Transportation In The JIT Inventory Management Model

July 26, 2023

Just-in-Time (JIT) is an inventory management strategy that has a company receiving goods when needed to meet customer demand—and not before. JIT has its roots in the automotive industry and was originated by the Toyota Motor Company™. Toyota™ discovered they could adapt more quickly to changes in demand by not keeping excess inventory on hand. Instead, they could have material delivered hours before needed directly to the assembly station where it would be promptly installed.

The purpose of JIT is to eliminate excess inventory and optimize operational efficiency. JIT Transportation (also known as JIT delivery or JIT logistics) and precise demand planning are integral parts of this strategy as it ensures goods are delivered as production is scheduled to begin. The JIT strategy can have sizeable benefits when strategically and meticulously carried out. One of the key takeaways of avoiding risk in a JIT inventory management strategy is the need for a reliable supply chain and high-quality, dependable transportation providers.

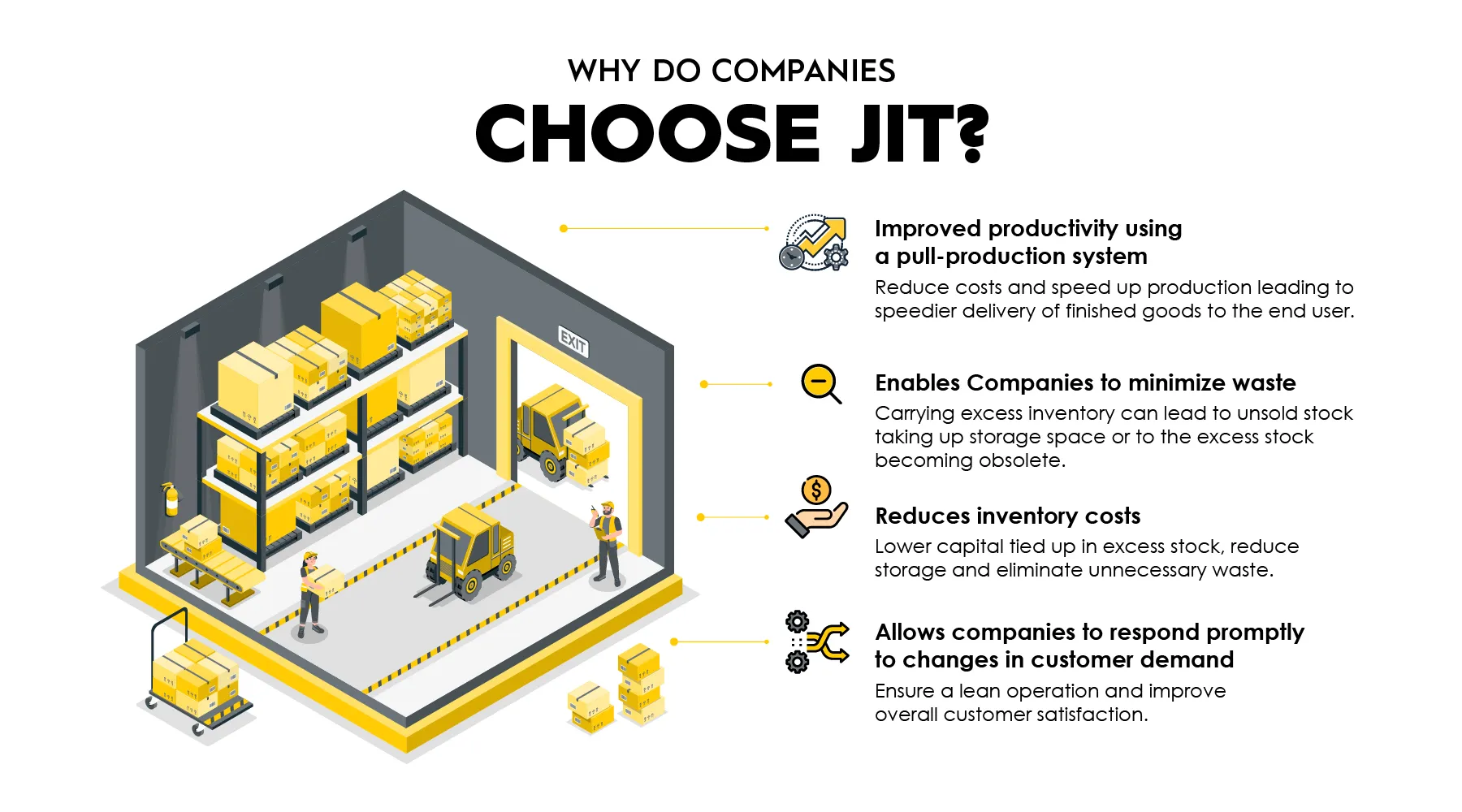

What Are The Benefits Of Using Jit Inventory Management?

When executed properly, the JIT inventory management strategy can help businesses increase operational efficiency, decrease waste, lower carrying costs associated with storing excess inventory, and increase profitability.

- Improved productivity is a key benefit to JIT. In contrast to the traditional push-production approach based on forecasted demand, JIT uses a pull-production system that involves manufacturing only what is needed, when it is needed, and in the quantity required to satisfy the current demand. JIT helps to reduce costs and speed up production leading to faster delivery of finished goods to the end user, thereby increasing customer satisfaction.

- JIT enables companies to minimize waste and unnecessary storage costs. Carrying excess inventory can lead to unsold stock taking up space or to excess stock becoming obsolete. Further, when there is excessive inventory to use up, batches of defective material can take longer to find and, if located outside the supplier’s return window, can lead to high scrap costs. Excess inventory can also lead to storage-related damage.

- Maintaining low stock levels by following a JIT inventory management strategy reduces inventory costs by lowering capital tied up in excess stock, reducing storage and handling fees, and eliminating unnecessary waste.

- JIT also allows companies to respond promptly to changes in customer demand, ensuring a lean operation and improved overall customer satisfaction.

What Are The Risks Of Jit?

Supply chain disruptions: Any interruption or delay in the supply chain can have severe repercussions, causing production line shutdowns and revenue losses.

- Market prices: Purchasing material on demand could cause companies to miss opportunities to save money when prices are low. Instead, purchasers could end up paying more for material because they have no buffer stock to wait out temporary price increases. When costs increase, it cuts into profit margins.

- Supplier Limitations: There is a high dependency on suppliers to deliver quality goods on time to meet demand. This limits a company’s ability to explore new and possibly better suppliers. Their reliance on their current supplier network can potentially leave them in a risky situation if service from those suppliers starts to decline rapidly or they are suddenly unable to meet demand.

- Acts of Nature: Weather, natural disasters, equipment breakdowns, political unrest, and other uncontrollable and unforeseeable “Acts of Nature” can cause the delivery of material to be severely delayed and production to be halted.

- Missed Opportunities: If there is a sudden surge in demand, the company may be unable to fulfill that demand because they do not have the material available to increase production quickly. This could drive customers to competitors to obtain the products they need.

Subscribe!

Subscribe to receive the latest articles, newsletters, whitepapers, and industry news directly to your inbox.

"*" indicates required fields

Executing A Jit Inventory Management Strategy

Proper execution is crucial for successful JIT inventory management. Here are some key things to consider before implementing a JIT strategy:

- Can the material or components needed in my manufacturing process be produced quickly enough to meet demand?

- Are my suppliers, such as my transportation provider, reliable enough to deliver quality material on time when I need it?

- Can my production schedule adapt to Acts of Nature or vendor failures that could cause disruptions in production?

- Is my inventory management system able to support a JIT inventory management strategy?

- Are my forecasts accurate? Do I have a solid understanding of the seasonal demands for my product?

SELECTING JIT VENDORS

Risk management in the JIT inventory management model is crucial and largely depends on reliable vendors. To ensure a successful implementation of the JIT model, companies must strategically source vendors that:

- Provide high-quality products or services

- Have a proven track record of success

- Offer fair prices

Vendors should not be selected because they are cost-leaders at the expense of quality and reliability.

JIT Transportation

JIT Transportation plays a critical role in JIT Inventory Management. Scheduling pickups and deliveries is equivalent to choreographing a complicated dance routine – all the steps and movements must be perfectly timed and executed together to make it work.

A competent 3PL is an ideal partner as their extensive carrier network and industry expertise enable them to navigate time-sensitive shipments effectively. Unlike asset carriers, a 3PL offers greater flexibility and scalability, reducing the risk of disruptions and ensuring seamless operations.

Despite meticulous planning, unforeseen issues can arise. However, how these challenges are handled makes a difference. Proactive communication from a 3PL partner is essential. With regular updates and by leveraging live tracking technology, a 3PL partner can help JIT customers react to disruptions in their supply chains effectively and help them reduce associated costs.

A strategic 3PL partner will also offer services such as Expedited transportation, which can save the day when things go wrong. Whether it’s an act of nature, an accident, or delays at supplier facilities, expedited shipping offers a cost-effective solution to get goods on-site quickly. A 3PL with an Expedited division can leverage its network and expertise to speed up shipments while providing continuous 24/7 updates to customers.

What Is The Difference Between Jit Transportation And Expedited Shipping?

While related, it’s important to distinguish between JIT and Expedited Services:

- JIT Transportation is a meticulously planned transportation operation that sees goods delivered to the manufacturer precisely when needed.

- Expedited services, on the other hand, cater to urgent delivery requirements, enabling businesses to meet immediate customer demands.

- Both approaches complement each other, and a well-executed Expedited Service can help overcome JIT-related challenges.

What Makes A Good Jit Transportation Partner?

Building solid relationships with trusted 3PLs is essential when working with time-sensitive shipments. Trustworthy 3PLs with a proven track record can significantly reduce the risk of disruptions. A 3PL can be invaluable in navigating a vast network of carriers because they have intimate knowledge of each carrier’s strengths and limitations.

Open and proactive communication is critical to mitigating risk. Look for 3PLs, like TRAFFIX, that focus on hiring highly trained and experienced transportation experts to manage JIT supply chains. Experience will allow the 3PL team to head off potential risks, analyze the supply chain, make recommendations to improve costs and efficiency, and react quickly to disruptions with cost-effective solutions. Experienced transportation partners understand that keeping customers informed about any delays, breakdowns, or supply chain disruptions, enables companies to keep production lines moving. Sharing real-time updates and utilizing tracking tools empower customers to adapt their processes accordingly.

To learn more about how TRAFFIX can be a valuable JIT Transportation partner to your business, contact us today!