Authored by Matthew Brachmann, Director of Drayage at TRAFFIX

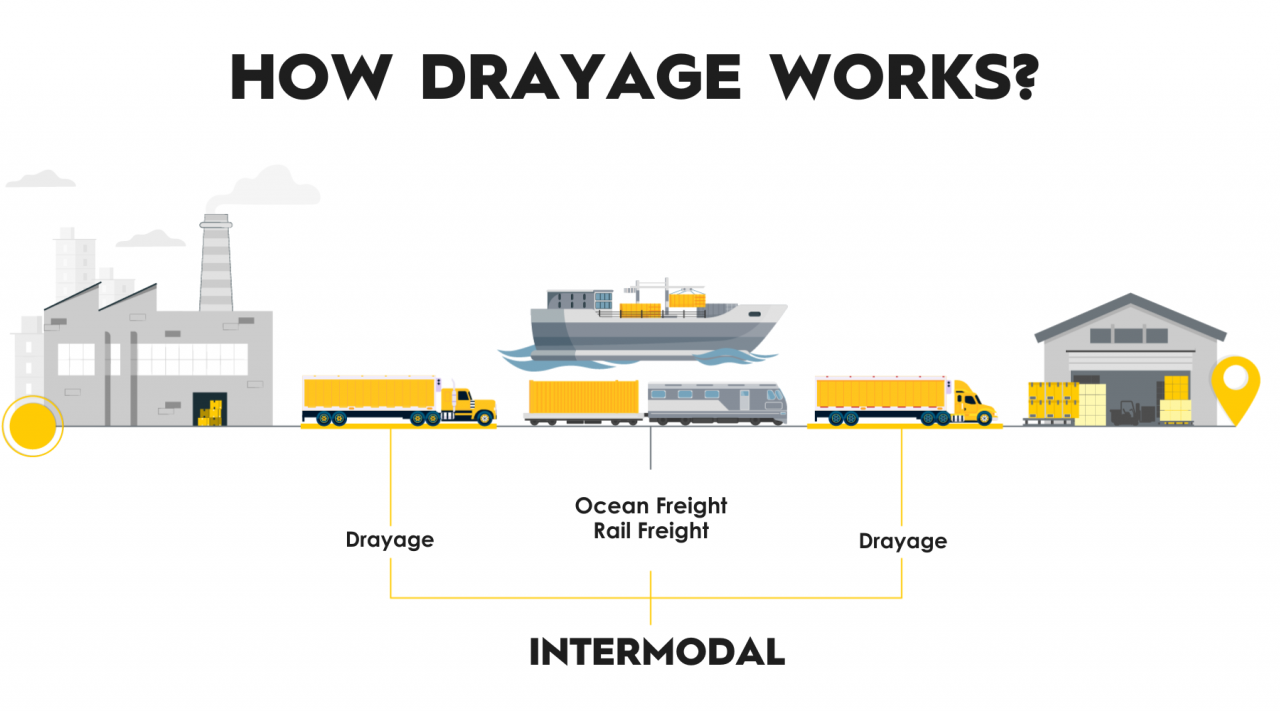

In the vast and intricate world of logistics, moving goods from one point to another is a highly complex process involving various modes of transportation. Supply chains involving the use of ocean or rail depend on drayage to link shippers and receivers to ocean ports and rail terminals. According to the Intermodal Association of North America (IANA), 95% of all manufactured goods worldwide utilize drayage at some point in the supply chain.

UNDERSTANDING DRAYAGE

Drayage refers to the short-haul, over-the-road transportation of goods from shippers to origin ocean ports or rail terminals; and from destination ocean ports or rail terminals to receivers.

Freight shipped by ocean or rail requires the use of containers. For this reason, drayage utilizes standardized equipment designed to transport containers to and from ocean ports and rail terminals without requiring them to be destuffed and transloaded.

An effective drayage partner will ensure the transportation of goods to and from ocean ports or rail terminals is executed efficiently to avoid disruptions throughout the supply chain.

HISTORICAL ROOTS OF DRAYAGE

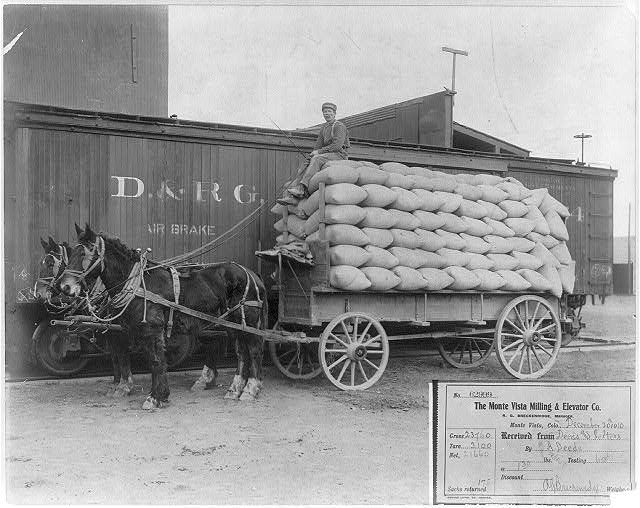

The history of drayage dates back to the 1800s when horse-drawn carts, known as “drays,” transported goods between warehouses, ocean ports, canal docks, and rail terminals, giving rise to the term “drayage.” Over time, semi-trucks and chassis replaced horses and drays, and drayage became an essential link between shippers, receivers, and other modes of transportation.

[Horse-drawn wagon (or “dray”) loaded with 175 sacks of wheat beside freight car], Library of Congress, LC-USZ62-45617

[Horse-drawn wagon (or “dray”) loaded with 175 sacks of wheat beside freight car], Library of Congress, LC-USZ62-45617

DRAYAGE CLASSIFICATIONS AND THEIR ROLES

Drayage can be classified into several categories, each serving specific purposes within the logistics industry:

-

Inter-Carrier Drayage: Involves moving freight between different modes of transportation, for example, moving cargo from an ocean port to a rail terminal.

-

Intra-Carrier Drayage: Describes moving cargo from one point in a transportation hub to another, for example, transporting a container from its staging area onto a ship in the same port.

-

Door-to-Door Drayage: Refers to transporting freight directly to the receiver from the ocean port or rail terminal.

-

Shuttle Drayage: When transportation hubs reach capacity, containers must be temporarily stored at offsite locations until capacity becomes available. Shuttle drayage involves moving those containers between the temporary storage site and the transportation hub.

-

Pier Drayage: Refers to transporting freight from a rail terminal to an ocean port to be loaded on a ship.

-

Expedited Drayage: Involves the swift and efficient transport of time or materially-sensitive freight.

SHIPPING CONTAINERS

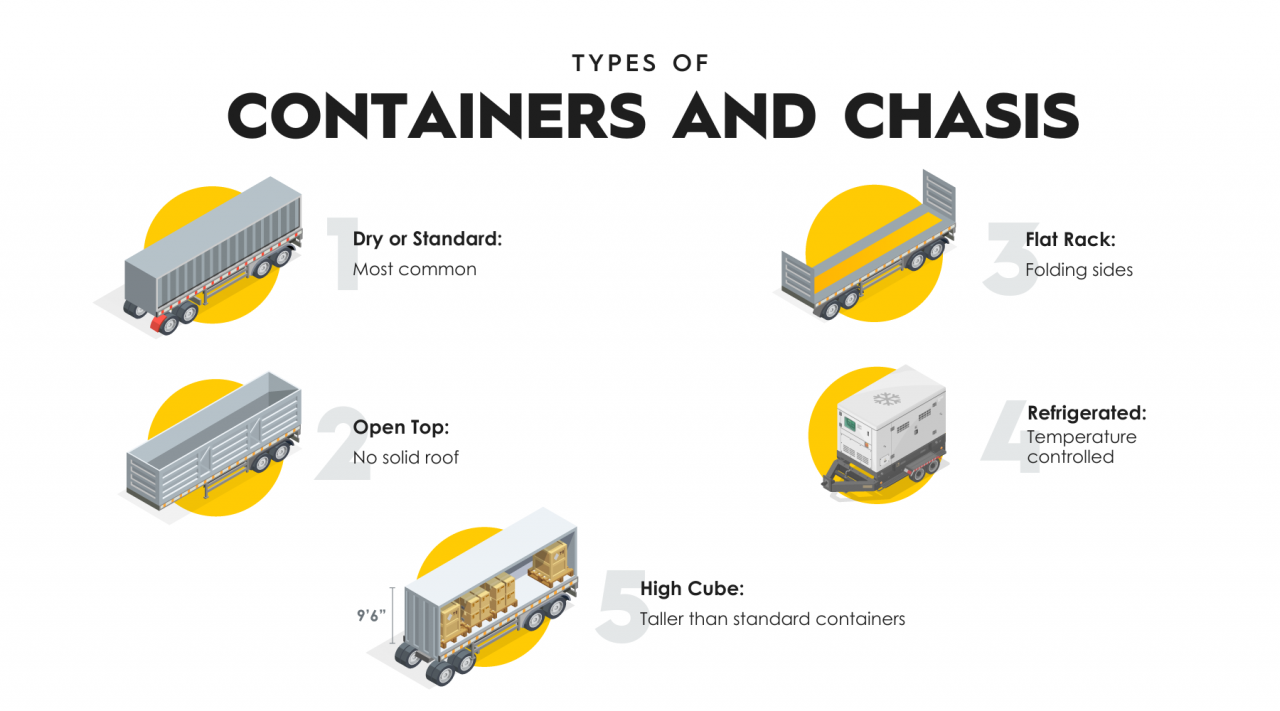

Shipping containers can range from 6-8.5 feet tall and usually come in lengths of 20, 40, or 45 feet. These containers are available in standard sizes to facilitate loading, unloading, and shipping across various modes of transportation. They are usually made of aluminum or steel and come in several different types, including:

- Dry or Standard: This is the most common type of shipping container used for transporting general cargo.

- Flat Rack: Flat rack containers have sides that can be folded to accommodate oversized or unusually shaped freight.

- High Cube: High cube containers are one foot taller than standard containers, at 9’ 6” tall outside and 8’10” tall inside, which offers more space and the ability to carry heavier weights than standard containers.

- Open Top: Open top containers do not have a solid roof and are typically covered with a tarp. They are often used to transport heavy machinery or cargo too tall for other containers or too heavy to be loaded through the doors.

- Refrigerated: Also known as reefer containers, these containers have temperature controls to maintain a constant temperature during transportation.

FINDING THE RIGHT DRAYAGE PARTNER

A reliable North American third-party logistics provider (3PL) with a drayage division, like TRAFFIX, has extensive networks of vetted drayage carriers and well-established relationships with ports and rail terminals across the continent. 3PL experts in drayage can customize solutions that ensure freight moves efficiently through the supply chain without disruptions. They have the experience to proactively head off challenges such as port congestion and capacity shortages to help shippers avoid fees and delivery delays while offering consultation on preparing for peak seasons and other potential disruptions.

By utilizing a 3PL like TRAFFIX, businesses can benefit from their expertise and experience in managing their drayage operations, allowing them to focus on their core competencies.